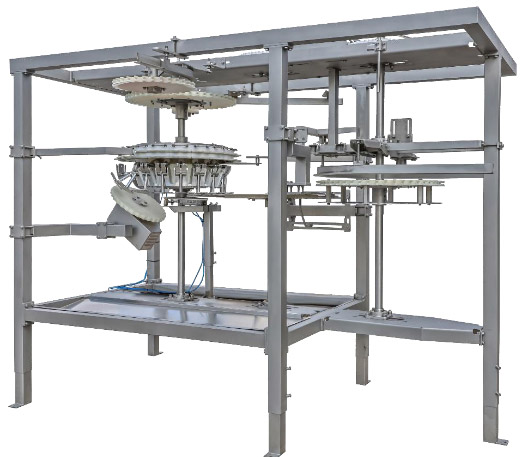

Automatic Carcass Rehanger - from EV to Chill

Type: APT-P-S

Carcass Re-hanger Overview

The carcass re-hanger is specifically engineered for transferring carcasses from the evisceration line to the chilling line. It is designed to handle chickens weighing 800-3,500 grams. For optimal re-hanger performance, it is essential that the batch weight range remains balanced.

Operation:

Both the evisceration lines and chilling lines are equipped with transmission and rotation generators. These generators are linked to the machine's electronic control system, which synchronises the speeds of the two lines. The re-hanger receives power from both evisceration and chill lines, ensuring their speeds remain synchronised through the electronic control system.

During operation, chickens are delivered into the re-hanger from the evisceration line. Inside the machine, an automatic mechanism lifts each chicken from the evisceration shackle and transfers it to a central wheel. The central wheel then transfers the carcasses to the chill line shackle for the next stage of processing. We have transfers that can work with any combination of shackle centres/spacings.

Technical Specifications:

Motor power: 0kW

Standard overall dimensions:

Length: 2,900mm

Width: 1,500mm

Height: 2,300mm

Weight: 870kg